Enhancing Resilience of Customers and Society

The Daigas Group aim to utilize our strengths in solutions and innovation and create value together with stakeholders, thereby enhancing the resilience of our customers and society.

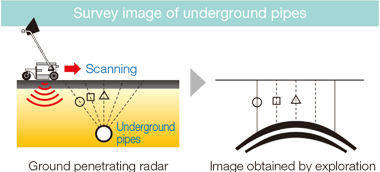

Development of “AI Radar Locator,” Which Uses AI to Locate Underground Pipes

The Daigas Group has developed and uses an “AI radar locator” that allows anyone to easily detect underground pipes with a high degree of accuracy, thanks to the adoption of AI image diagnostic technology. The radar locator emits radio waves toward the ground, and generates survey images based on the reflection of the waves from underground pipes. Operators can then estimate the location of underground pipes by interpreting the shape of the waves in the images. There were cases in which it was difficult to detect locations depending on the status of pipes and the quality of soil, and it required significant technical skill to identify the location of underground pipes with certainty. In this development, however, the AI system that learns the judgment of experienced workers enabled operators to automatically make judgments about the location of underground pipes, without relying on the expertise of them. We will focus on further technical development for enhancing the safety of our gas operations in order to ensure that our customers can continue to use gas safely and with peace of mind.

-

Gas pipes survey using a radar locator

-

-

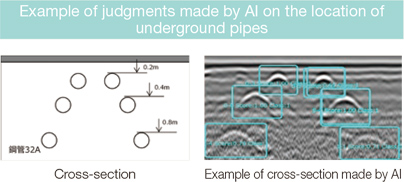

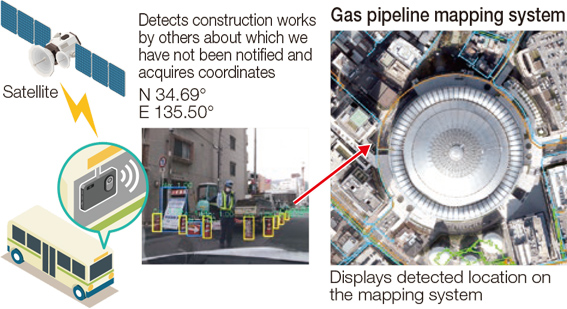

Move to Absolute Coordinates for Pipe Mapping Systems

The Daigas Group manages location information of gas pipes with a mapping system to implement construction, maintenance, and operations. Previously, this location information was expressed in the form of relative coordinates based on geographical features such as roads and rivers on a topographic map. As such, in order to identify the location of gas pipes at sites, it was necessary to measure the distance from the origin of the relative coordinates. There were cases where the location of the origin needed to be changed because of road construction or other reasons, requiring significant labor for maintenance. Now, we have replaced the maps used in our pipe mapping system with high-accuracy and high-resolution aerial photographs with absolute coordinates, thereby proceeding with our efforts to allocate absolute coordinates to gas pipes. As a result, we will be able to identify the location of gas pipes with pinpoint accuracy, even when it has become impossible to identify the origin of relative coordinates due to road expansions or sediment deposition caused by natural disasters, and other reasons.

Using the location information of gas pipes expressed in absolute coordinates, we began a trial operation utilizing AI for gas pipe patrols, jointly with Osaka City Bus Corporation, starting in June 2021. For roads where medium-pressure gas pipes are buried, we have traditionally been taking steps to prevent damage to the gas pipes by operating patrol cars that travel along designated routes every day to detect any construction work in the vicinity of the gas pipes that are not notified to the Group. Now, we have developed a camera that automatically recognizes construction sites by using AI systems, and have installed the camera in route buses along with GPS, thereby making efforts to identify construction works taking place in the vicinity of mediumpressure gas pipes on the bus routes. By so doing, we will be able to increase the frequency of patrols and enhance safety quality, while also increasing the productivity of our operations.

In the future, it will become possible to identify the location of gas pipes even with general-purpose devices such as smartphones, by managing the location information of gas pipes based on absolute coordinates. This also offers the prospect of future transformations in operations, etc. We will continue enhancing the quality of our operations from the perspective of ensuring safety and preventing disasters to improve the resilience of our customers and society.

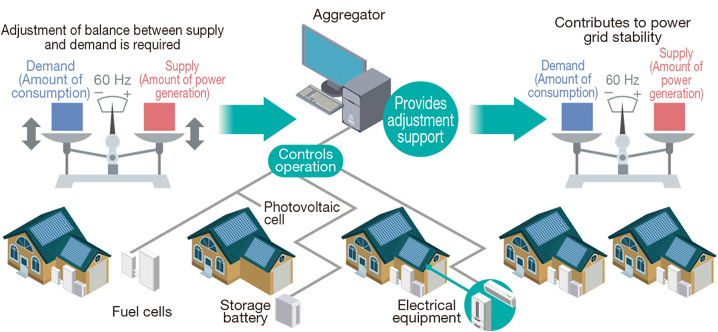

Launch of Verification Project to Establish Virtual Power Plant (VPP) Using Residential Fuel Cell “ENE-FARM” —VPP Verification Project Connecting 3,600 Units—

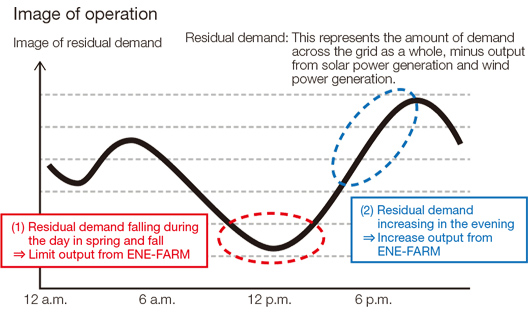

Electricity cannot be stored, so continual adjustments of power generation must be made to ensure a balance between supply and demand. If power generation is not balanced, the frequency of the electricity will fluctuate, potentially resulting in large-scale power outages, in the worst-case scenario. As a result, general electricity transmission and distribution utilities currently maintain frequencies within a certain range, mainly by limiting the output of power stations to match demand.

Renewable energy, which does not generate CO2 when electricity is generated, may become a key energy source in future under Japan’s energy policies. Still, solar power generation and wind power generation are affected by weather conditions such as the amount of solar radiation and strength of the wind, causing issues when adjusting the balance of grid electricity supply and demand. On the other hand, fuel cells have the characteristic of being able to freely control the output of power, and are attracting attention as a resource that can contribute to the adjustment of grid electricity supply and demand in a society in which a large amount of renewable energy is introduced.

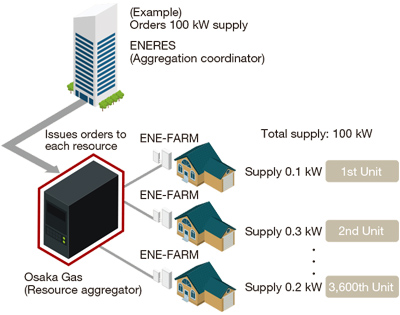

■ Concept of VPP

Innovation by the Daigas Group

Osaka Gas is conducting a verification project to build a virtual power plant (VPP)*1 that controls approximately 3,600 units of the residential fuel cell system, “ENE-FARM,” installed at customers’ homes (a total potential supply capacity*2 of around 1 MW) as energy resources as if it were a single power plant, so as to utilize it for effective adjustment of grid electricity supply and demand and for avoiding imbalance in the grid. While the aggregation coordinator*3 in this verification project is ENERES Co., Ltd., Osaka Gas participates in the project as a resource aggregator*4.

In the previous fiscal year, the Company participated in a verification project for a VPP that involved verifying the operation of over 1,500 ENE-FARM units. This fiscal year, we intend to conduct a technical verification that aims to provide adjustment capabilities with the use of approximately 3,600 ENE-FARM units, exceeding the previous fiscal year, while also aiming to enhance the accuracy of controlling ENEFARM units remotely in accordance with the supply-demand balance in the grid. Additionally, it has been required to avoid imbalances of renewable energy ahead of the introduction of the FIP scheme. Therefore, in this verification, the Company will verify the technology used to avoid imbalances by controlling the power generated by ENE-FARM units in accordance with the output of power from our Yura Solar Power Plant.

- *1 Virtual power plant. It is utilized by a business operator called “aggregator” that aggregates the adjustment capacity supplied by distributed power sources

- *2 The amount of adjustment capacity that can be offered to the market

- *3 A business operator who aggregates the electric power controlled by a resource aggregator, and trades electricity directly with general electricity transmission and distribution utilities and electricity retailers

- *4 A business operator who controls resources by directly concluding VPP service contracts with customers

- Management Plan

- Management Plan Documents Long-Term Management Vision2030/Medium-Term Management Plan 2026

- Daigas Group's Values

- Daigas Group's Values Daigas Group Corporate Principles Daigas Group Charter of Business Conduct Daigas Group Code of Business Conduct Our Declaration Daigas Group Policies

- Sustainability Management

- Promotion System Materiality of the Daigas Group Stakeholder Engagement History of Co-creation of Value Value Creation Process

- Environment

-

Environment

Environmental Management

Daigas Group Environmental Policy

Estimation Method of Environmental Accounting

Environmental Impact throughout the Daigas Group Value Chain

Environmental Targets

Actions for Climate Change

Assessment of CO₂ Emissions Reduction Effects

Disclosure Based on the TCFD Recommendations:

Recognition of and Action on Risks and Opportunities Contributing to the Resource-Recycling Society Data Trends Regarding Resource Recycling Information Disclosure on the Research Results of Soil and Groundwater Conservation Biodiversity Daigas Group Biodiversity Policy Development of Environmental Technology

- Social

-

Social

Innovation Management

Promoting Business Transformation with DX Research and Development/Intellectual Property/New Businesses Creation Human Resources Management/Human Resources Strategy Targets Human Resources Development DE&I (Diversity, Equity, and Inclusion) Daigas Group Diversity Promotion Policy Work-Life Balance Occupational Health and Safety Communication Between Employees and Company Human Rights

Respect for Human Rights throughout the Value Chain

Human Rights Due Dilligence

Action for Human Rights Daigas Group Human Rights Policy Supply Chain Management Daigas Group Procurement Policy Social Impact of Business Activities in Our Energy Value Chain Customer Health and Safety Customer Satisfaction Community

Co-creation Activities with Local Communities

Activities by Public Interest Incorporated Foundations

- Governance

- Governance Corporate Governance Dialogue between Outside Directors and Institutional Investors Compliance Consultations and Reports from Partner Companies Information Security Protect Personal Information

- Reporting Guidelines

- Global Reporting Initiative (GRI) Index SASB Table Reference for the Environmental Reporting Guidelines of the Ministry of the Environment TCFD Recommendations Table