Cogeneration (CHP) units

Miller-cycle Gas-engine Cogeneration

Overview

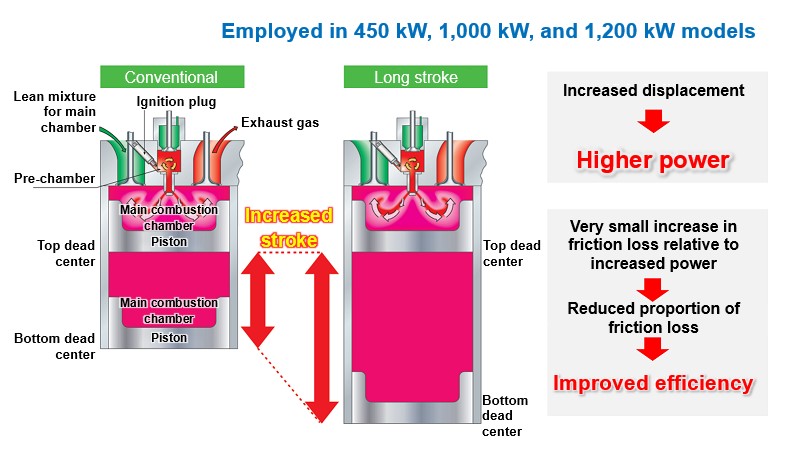

Osaka Gas is working on developing a high-efficiency gas engine jointly with Mitsubishi Heavy Industries Engine & Turbocharger, Ltd. In 2000, a Miller-cycle gas engine, the first in the world to achieve a power generation efficiency of 40% was launched. In 2002, the advanced Miller-cycle gas engine was released, which is a higher output and higher efficiency version of the Miller-cycle gas engine. In 2007, long stroke technology was employed to achieve even higher output and higher efficiency. About 200 units of these gas engines have been delivered to customers in the service area of Osaka Gas. In 2017, a 1,200 kW model was launched, which is the maximum-output, maximum-efficiency model.

To meet growing business continuity needs, in 2020, Osaka Gas started selling an 850 kW unit with radiator option, which can continue to operate even during water outage and achieves an initial load input rate of 30% of nominal load.

System Features

・A rich line of products ranging from 450 kW to 1,200 kW models

・Use of the Miller cycle to achieve the world’s highest-class power generation efficiency of 41.2% to 42.0%

・Equipped with a high-performance turbocharger

・High-durability parts developed to withstand high Pme

・High-performance ignition plug developed (joint development with Denso Corporation)

・Suitability for normal service use and for emergency use

・Compact package

* The 450 kW unit is not a product jointly

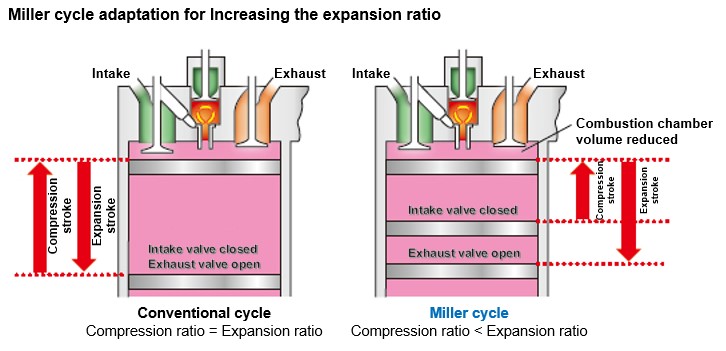

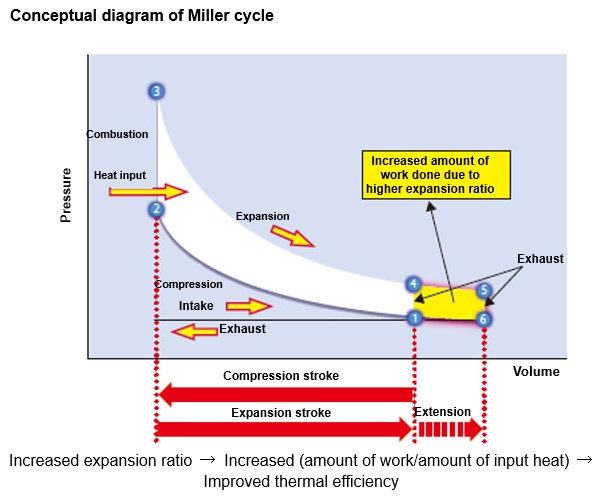

Principle of Miller Cycle

The Miller cycle is a cycle in which the expansion ratio is greater than the compression ratio and is also known as a high expansion ratio cycle. Since the combustion gases can be fully expanded in the engine, it is possible to increase the power generation efficiency.

Long-stroke Technology

Long stroke is a technique involving longer length of the piston stroke than that of cylinder bore. The long stroke technology enables the engine to deliver higher output at higher efficiency. On the other hand, increasing the output without changing the size of the intake valve and the exhaust valve makes it essential to develop a high-performance turbocharger and high temperature durable valves.

Related contents

TAG SEARCH

- Evolving residential gas appliances

- Evolving residential gas appliances Water heaters, space heaters, dryers Cooking appliances Smart Equipment Fuel Cell systems

- Evolving commercial and industrial gas appliances

- Evolving commercial and industrial gas appliances Cogeneration (CHP) units Air conditioning systems, kitchen appliances Bio, water treatment Industrial furnaces, burners Energy management, IoT

- Enhancing the safety and economic efficiency of LNG regasification

- Enhancing the safety and economic efficiency of LNG regasification Utilization of cold energy Plant materials Power generation technology

- Developing next-generation businesses through enterprising initiatives

- Developing next-generation businesses through enterprising initiatives Materials development Measurement Simulation, data analysis Food science Material evaluation

- Contributing to conserving the environment and achieving a carbon neutral society

- Contributing to conserving the environment and achieving a carbon neutral society Methanation Hydrogen, ammonia Biogas Energy management Renewable Energy

- Technologies of Group companies

- KRI, Inc. Osaka Gas Chemicals Group OGIS-RI Group