Air conditioning systems, kitchen appliances

Micro-cogeneration Waste-heat-input type Natural Chiller

Overview

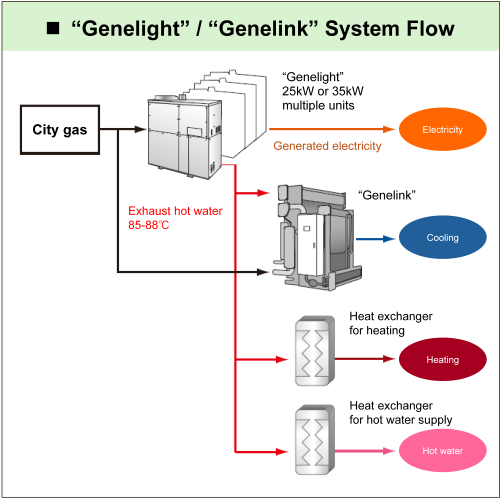

Until now, waste heat utilization for the waste-heat-driven absorption chiller "Genelink," which was supported by CGS in the 100kW to 300kW class, can now be handled by multiple units of the micro-cogeneration "Generight" in the 25kW and 35kW classes.

The conventional Generight had a low waste heat temperature of 65–75°C and was mainly limited to hot water supply applications, so expansion of its applications was desired. This time, by raising the waste heat temperature of Generight to 85–88°C, it has become possible for the first time in micro-cogeneration to use waste heat for cooling purposes.

About "Genelink":

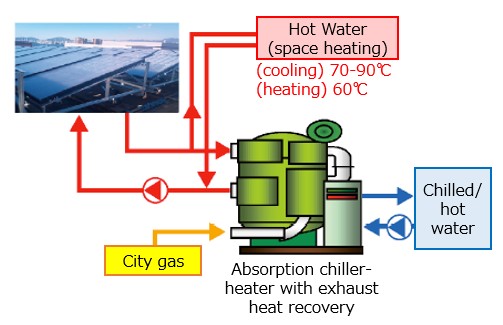

It is a system that installs a waste heat recovery heat exchanger between the absorber and the generator in the absorbent solution line of a conventional gas absorption chiller. By heating the absorbent solution with waste heat (hot water) from the gas engine, it reduces the amount of fuel gas consumed by the high-temperature generator.

Features

1.Wide Variety

The number of "Generight" units can be selected to match the "Genelink" lineup, ranging from 80RT to 800RT.

2.Energy Saving

Since the waste heat from "Generight" can also be effectively used for cooling, significant energy savings in air conditioning can be achieved.

3.High Economic Efficiency

High economic efficiency is realized through the high efficiency of the natural chiller, the high power generation efficiency of "Generight," low maintenance costs, and low initial costs.

4.Space Saving

With six units of "Generight" 35kW, approximately 50% space saving is achieved compared to a 200kW class CGS.

Related contents

TAG SEARCH

- Evolving residential gas appliances

- Evolving residential gas appliances Water heaters, space heaters, dryers Cooking appliances Smart Equipment Fuel Cell systems

- Evolving commercial and industrial gas appliances

- Evolving commercial and industrial gas appliances Cogeneration (CHP) units Air conditioning systems, kitchen appliances Bio, water treatment Industrial furnaces, burners Energy management, IoT

- Enhancing the safety and economic efficiency of LNG regasification

- Enhancing the safety and economic efficiency of LNG regasification Utilization of cold energy Plant materials Power generation technology

- Developing next-generation businesses through enterprising initiatives

- Developing next-generation businesses through enterprising initiatives Materials development Measurement Simulation, data analysis Food science Material evaluation

- Contributing to conserving the environment and achieving a carbon neutral society

- Contributing to conserving the environment and achieving a carbon neutral society Methanation Hydrogen, ammonia Biogas Energy management Renewable Energy

- Technologies of Group companies

- KRI, Inc. Osaka Gas Chemicals Group OGIS-RI Group