Materials development

Titanium-based Nanomaterials with Excellent Transparency, Coatability, and Photocatalytic Activity

- Overview

- Size and Features of Titania Sol

- Physical property 1: Decomposition of organic matter (titania sol)

- Physical property 2: Superhydrophilicity (titania sol)

- Physical property 3: Antibacterial and antiviral properties (titania sol)

- Physical property 4: Ultraviolet shielding (titania sol)

- Physical property 5: High refractive index (ultra-high refractive index material)

- Physical property 6: Energy conversion (titania nanoparticles)

- Physical property 7: Charge/discharge characteristics (titanate nanomaterials)

Overview

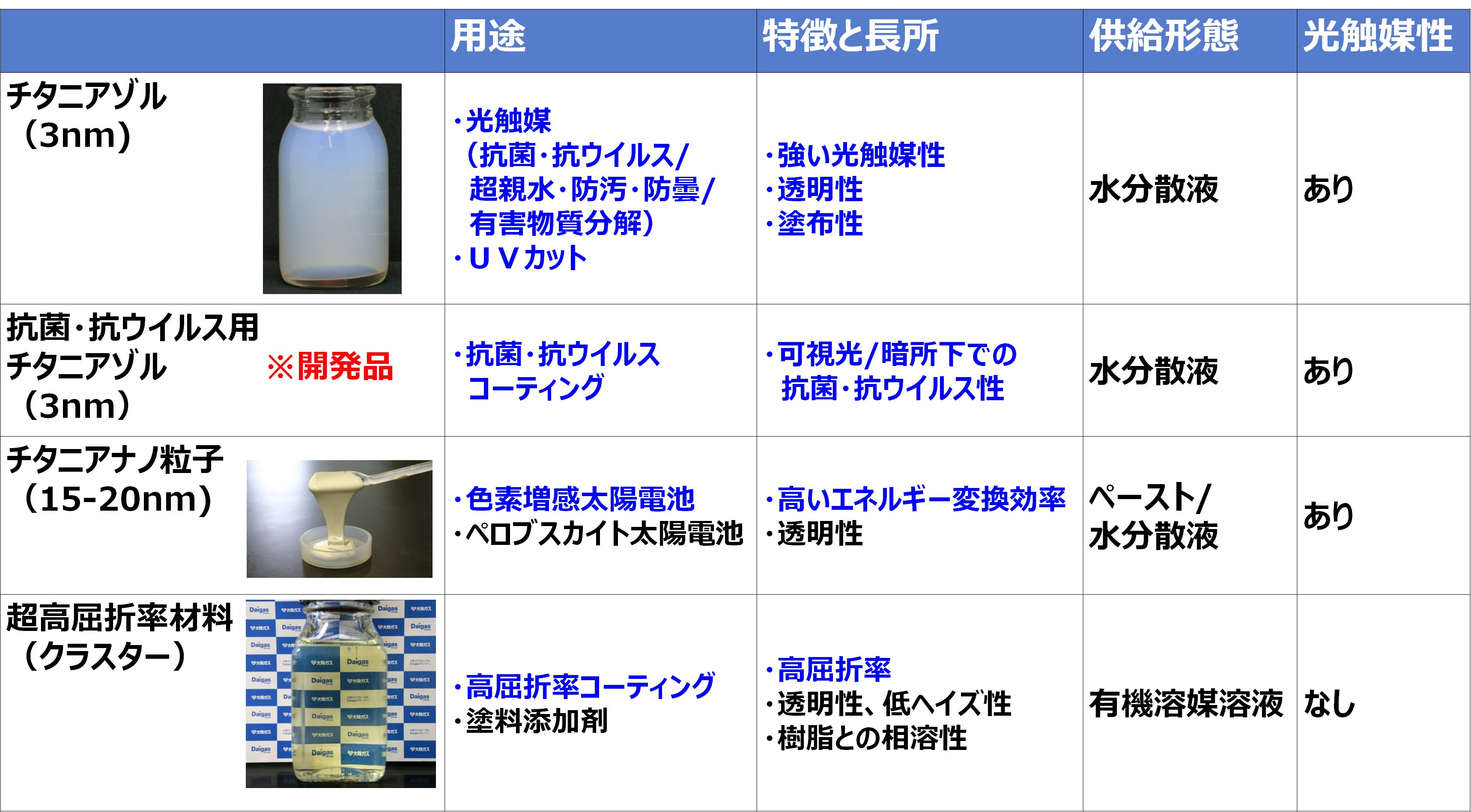

Osaka Gas creates titanium-based nanomaterials with various properties, such as superb transparency and coating properties, photocatalytic properties (antibacterial/antiviral properties, superhydrophilicity, decomposition of organic matter), energy conversion efficiency, UV absorption, high refractive index, and charge-discharge properties.

Fig. 1. Classification and features of titanium-based nanomaterials

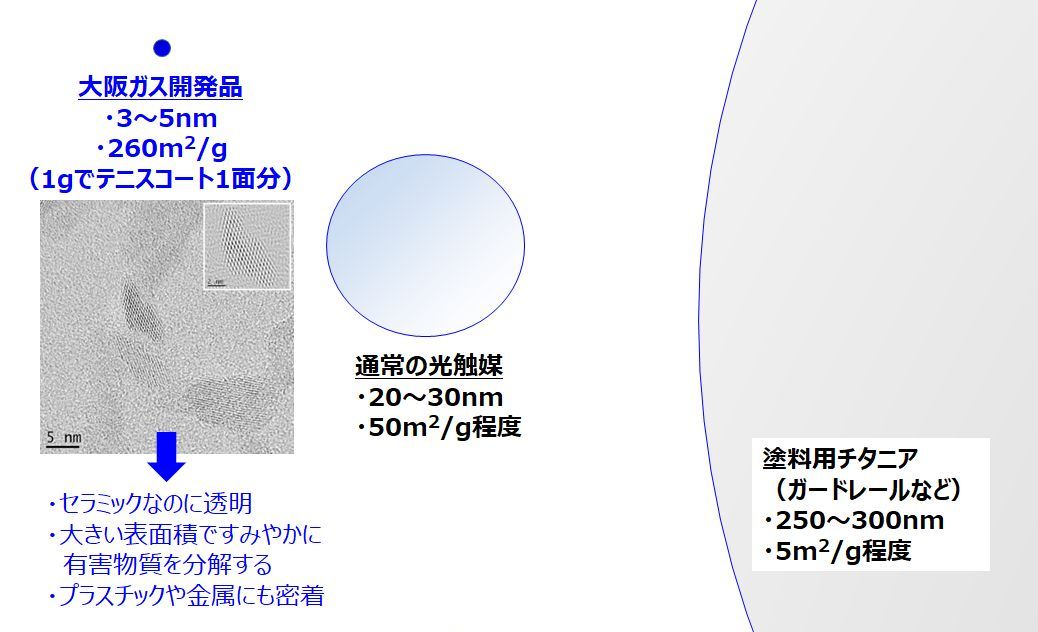

Size and Features of Titania Sol

Titania sols developed by Osaka Gas have a particle size of 3 to 5 nm, which is an order of magnitude smaller than that of general photocatalysts. Titania sol has a specific surface area of 250 to 300 m2/g (tennis court).It also solves the problem of agglomeration that tends to occur with particles with small diameters, making it highly practical.

【Transparency】

Normally, particles tend to aggregate and become more cloudy with decreasing particle size; however, this material has high dispersibility despite its small particle size and has exceptionally high transparency.

【Coatability 】

The high dispersibility of this material prevents cracking and peeling during drying, which is more likely to occur when particle diameters are small. The synergistic effect of the small particle size and the chemical structure of the surface enables the material to have excellent adhesion to the substrate.

【Photocatalytic Activity】

Despite its small particle size, the material is crystalline, so it has high photocatalytic activity and quickly decomposes organic substances and odors with its high specific surface area.

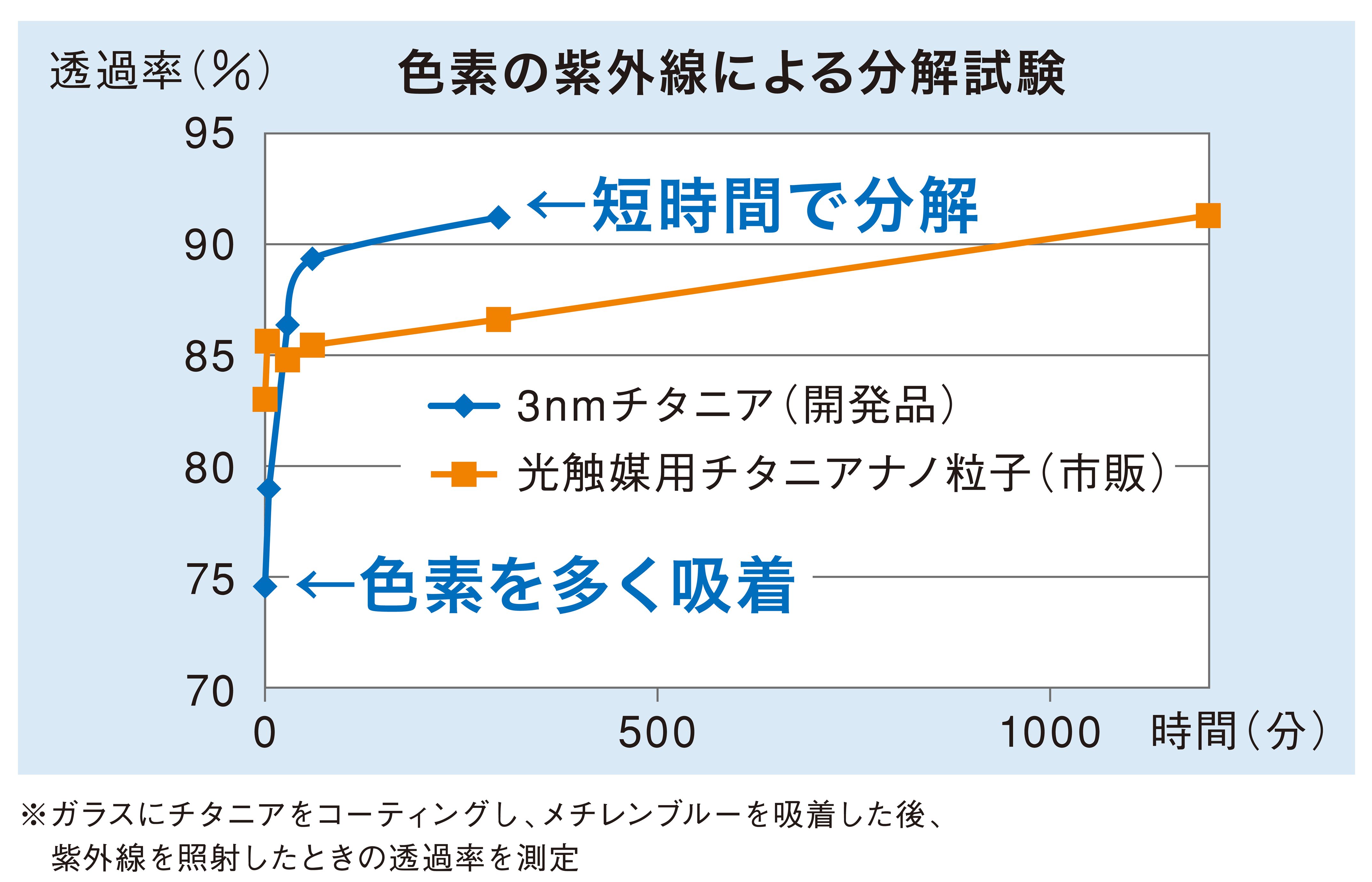

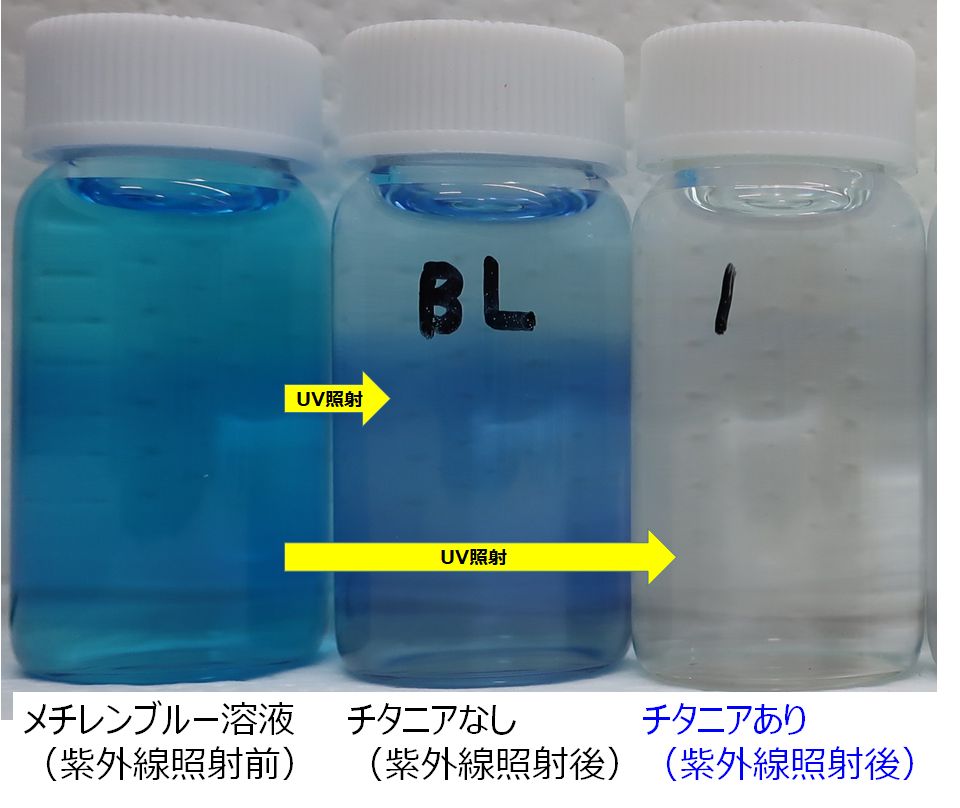

Physical property 1: Decomposition of organic matter (titania sol)

Titania sol can quickly adsorb and decompose various organic substances due to both photocatalytic activity and specific surface area.

Fig. 2. Comparison of rate of pigment decomposition by ultraviolet light

Fig. 3. Pigment decomposition test in a transparent bottle

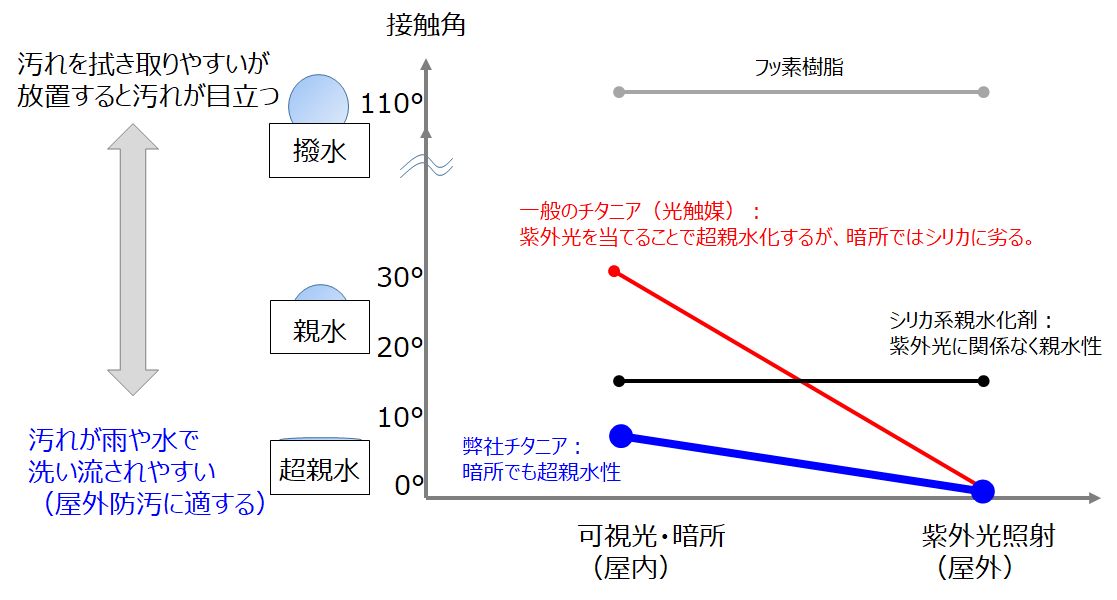

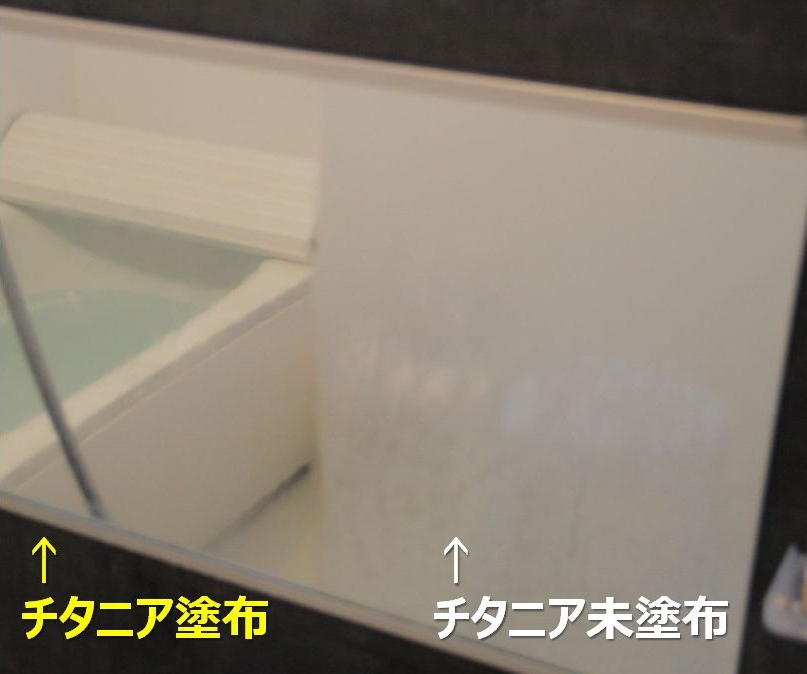

Physical property 2: Superhydrophilicity (titania sol)

Although the ultra-hydrophilicity of ordinary photocatalysts requires ultraviolet light, this titania sol exhibits hydrophilicity even in an environment without ultraviolet light and exhibits higher hydrophilicity than silica does in an environment with ultraviolet light.

Taking advantage of its transparency and superhydrophilicity, titania sol can be used as an antifouling or antifogging material.

Fig. 4. Hydrophilicity and transparency (left: coated; right: not coated)

Fig. 5. Hydrophilic features

Fig. 6. Making a mirror anti-fog in an environment without ultraviolet light

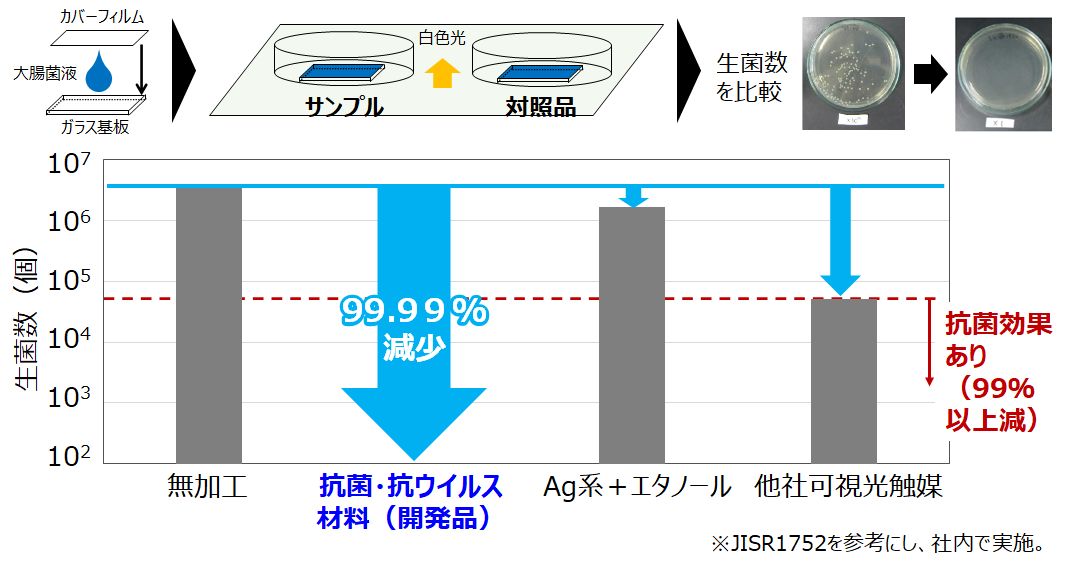

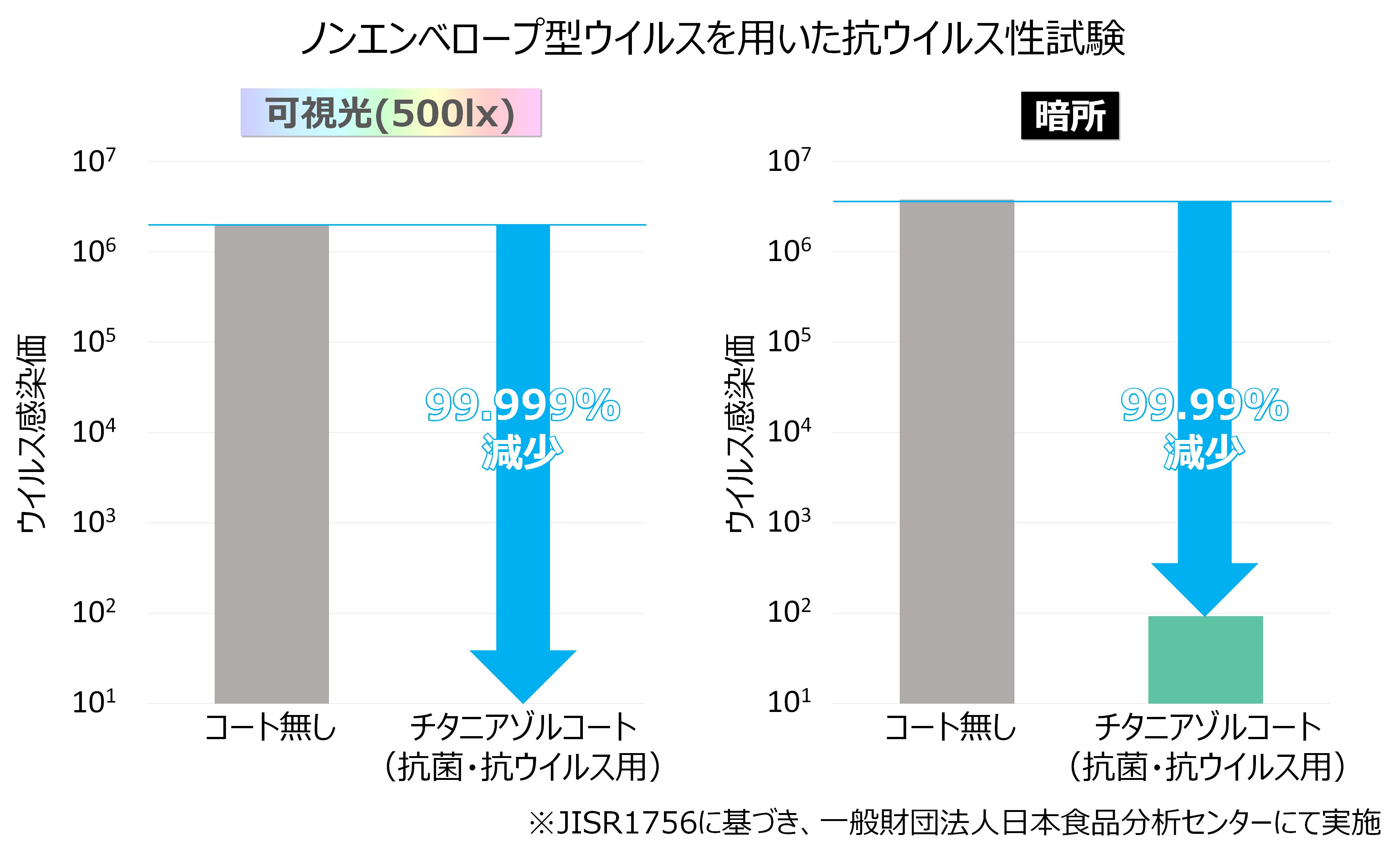

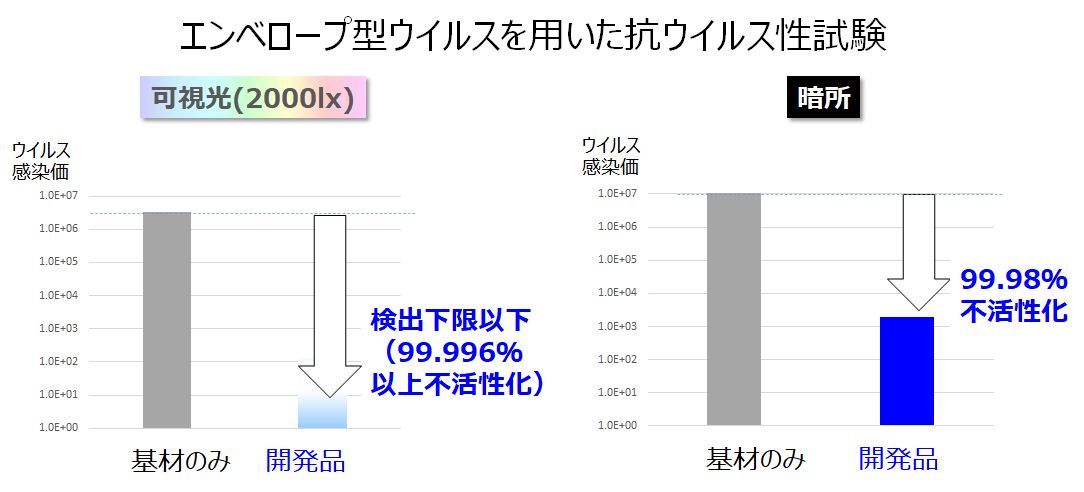

Physical property 3: Antibacterial and antiviral properties (titania sol)

Titania sol exhibits high antibacterial and antiviral properties when irradiated with ultraviolet light and can be used as a raw material for transparent, long-lasting antibacterial and antiviral coatings. It can be applied to various materials, such as glass, metal, plastics, and fibers, by taking advantage of its small particle size, dispersibility, and adhesion.

As early as before the spread of the novel coronavirus, Osaka Gas improved this material and started developing antibacterial and antiviral materials that are highly active even under visible light and in dark places.

(For more information on antibacterial and antiviral materials that are active in visible light and in the dark, please refer to another page)

Fig. 7. Antibacterial properties after friction testing (800 cycles)

Fig. 8. Efficacy against non-enveloped viruses

Fig. 9. Efficacy against enveloped viruses

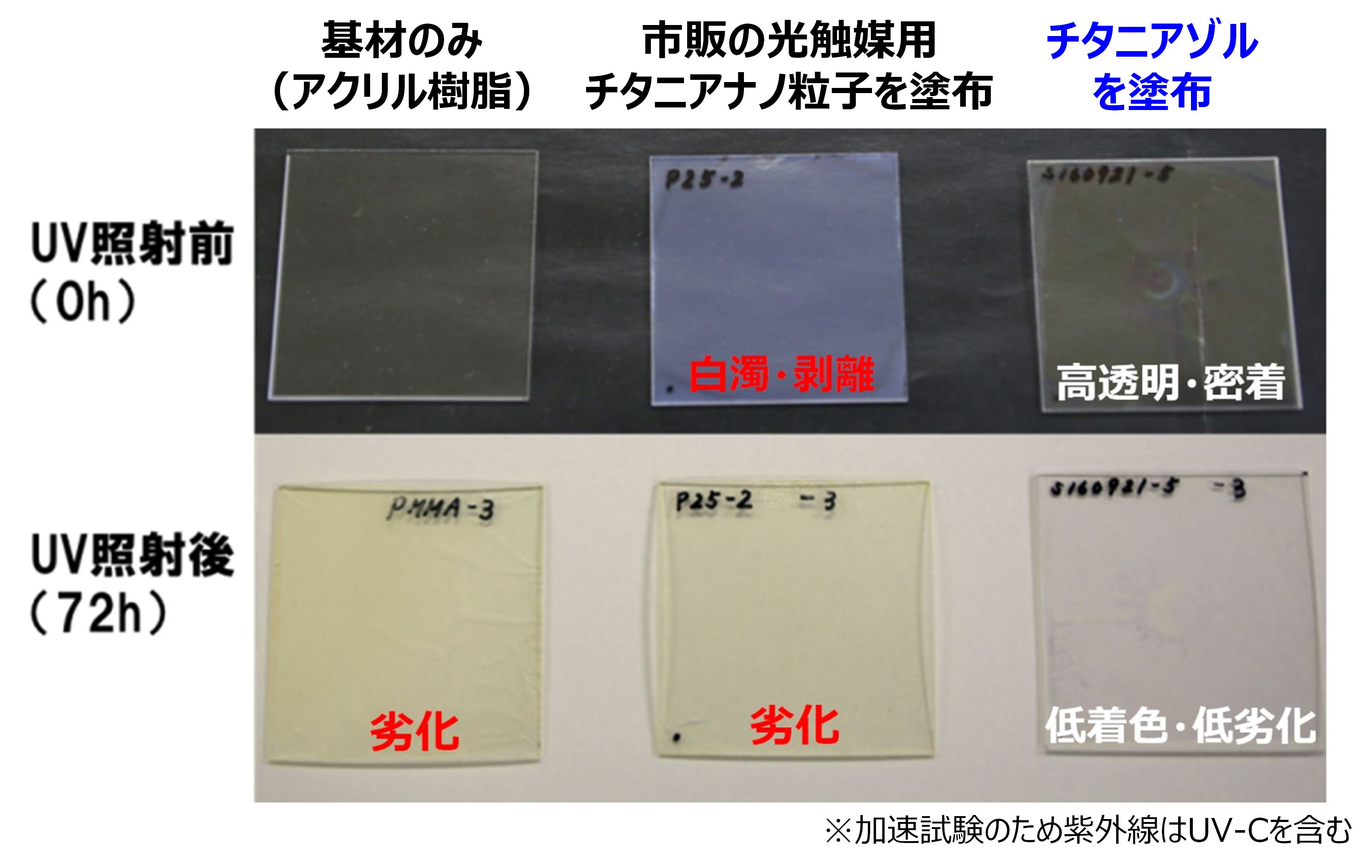

Physical property 4: Ultraviolet shielding (titania sol)

Titania sol blocks ultraviolet rays while being transparent, preventing deterioration in appearance and strength.

It can be applied to plastics such as PET, PMMA, and PC, although at varying applicability and adhesion with the type of plastic.

Fig. 10. Ultraviolet irradiation degradation test of coated acrylic substrates

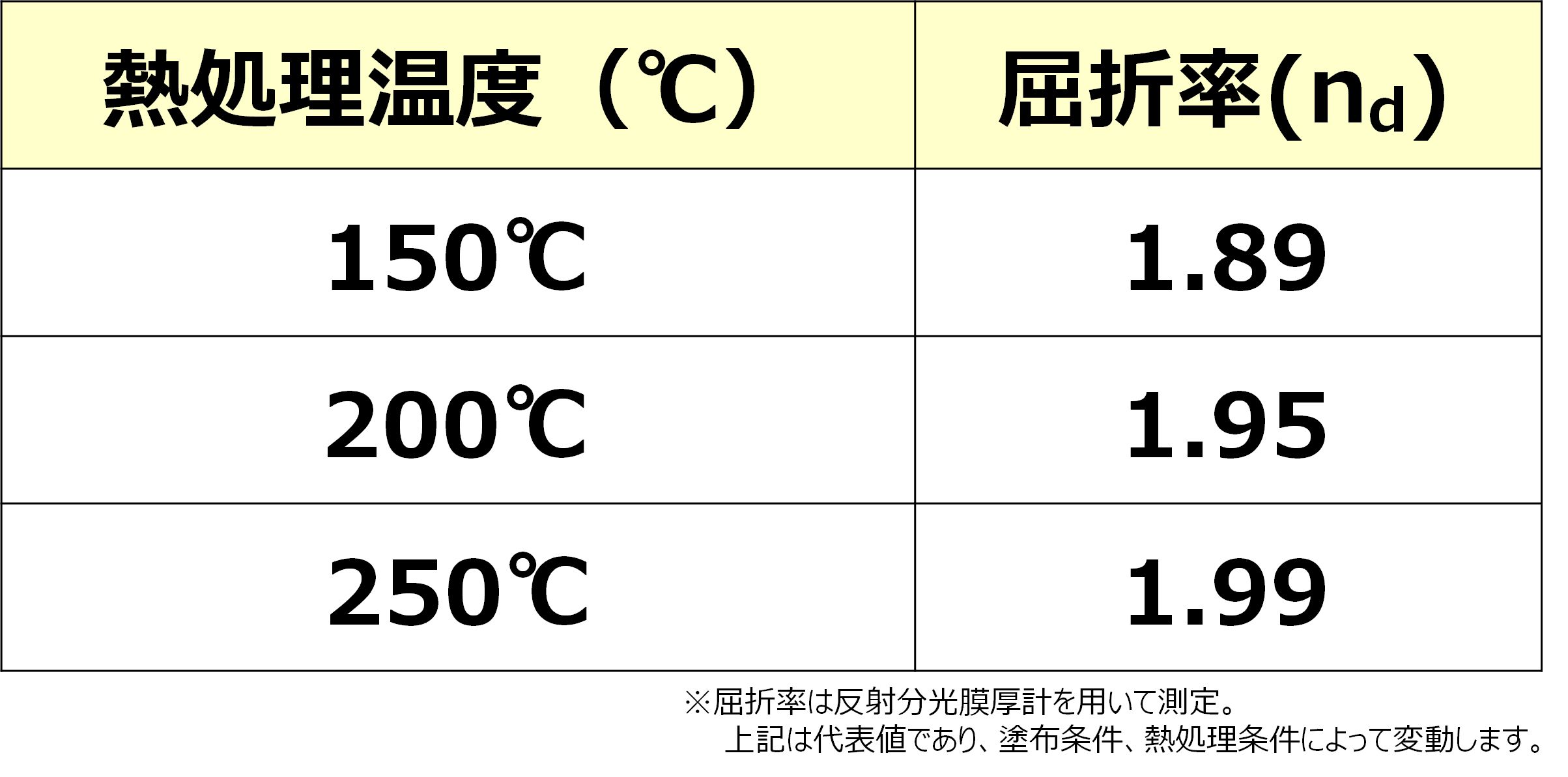

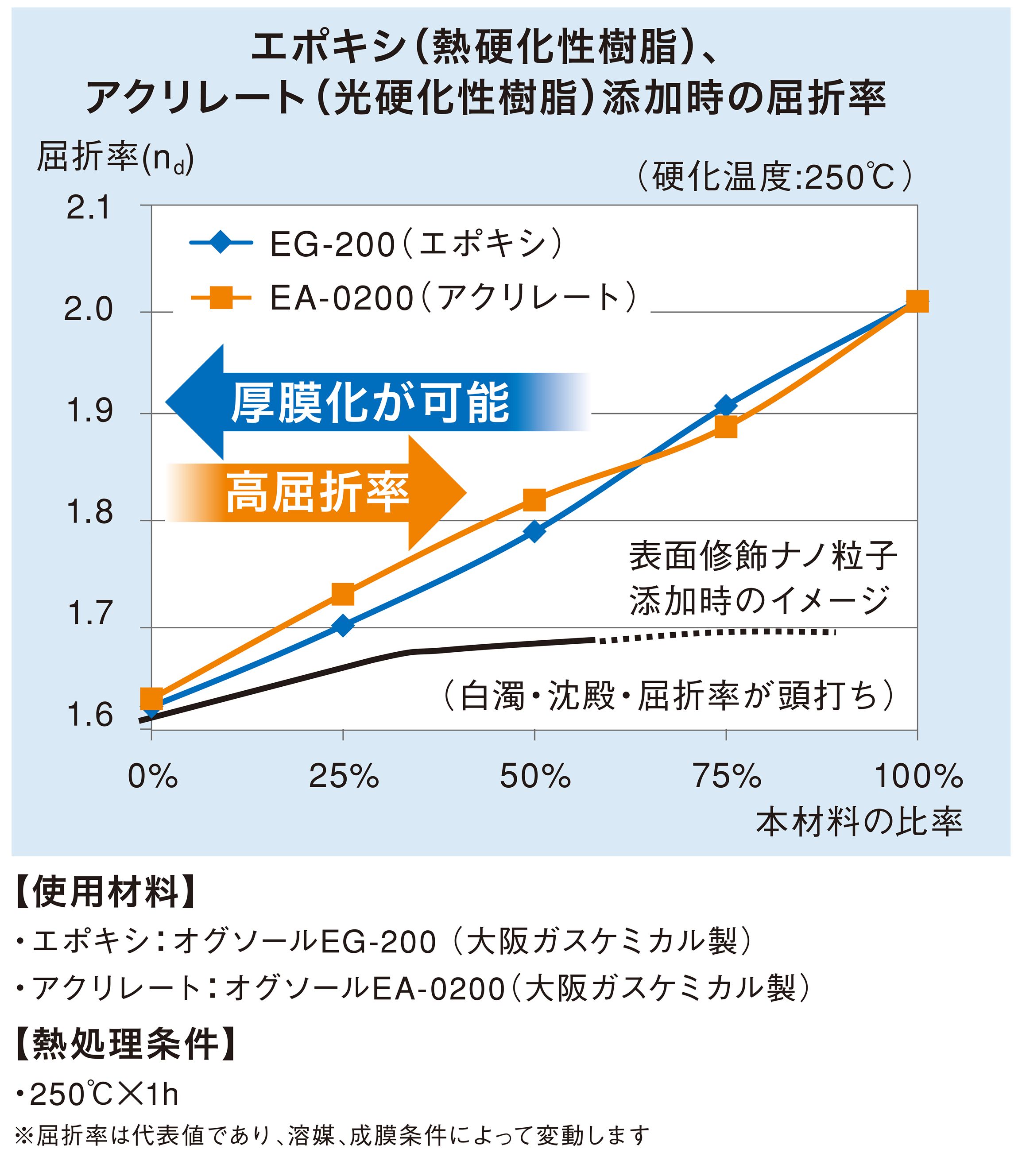

Physical property 5: High refractive index (ultra-high refractive index material)

The ultra-high refractive index material is an organic solvent solution of non-crystalline titania. Therefore, it has exceptionally high transparency and is not photocatalytic.

Since at low temperatures it exhibits a high refractive index not seen with organic materials, it can also be coated on plastics.

Unlike nanoparticles, it is compatible with epoxies (thermosetting resins) and acrylates (light-curing resins) at desired proportions.

Fig. 11. Liquid transparency comparison

Fig. 12. Refractive indexes of ultra-high refractive index materials

Fig. 13. Compatibility with epoxies and acrylates and refractive index

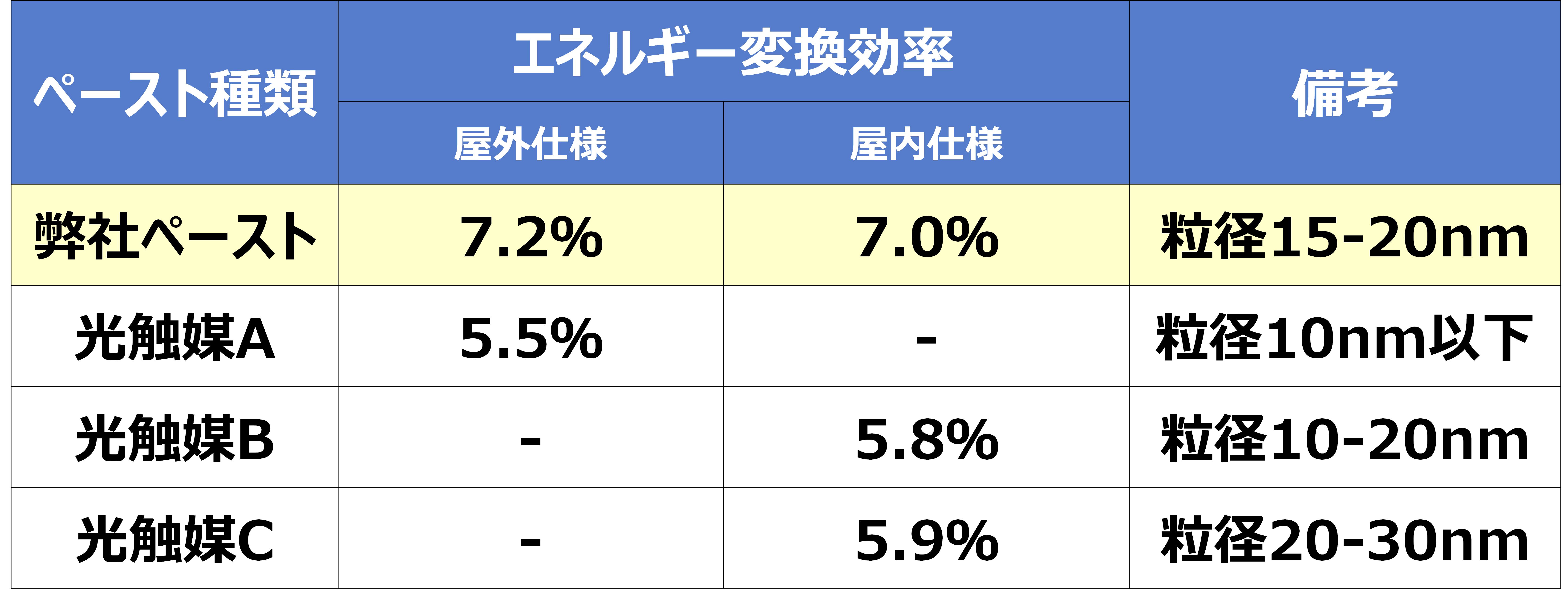

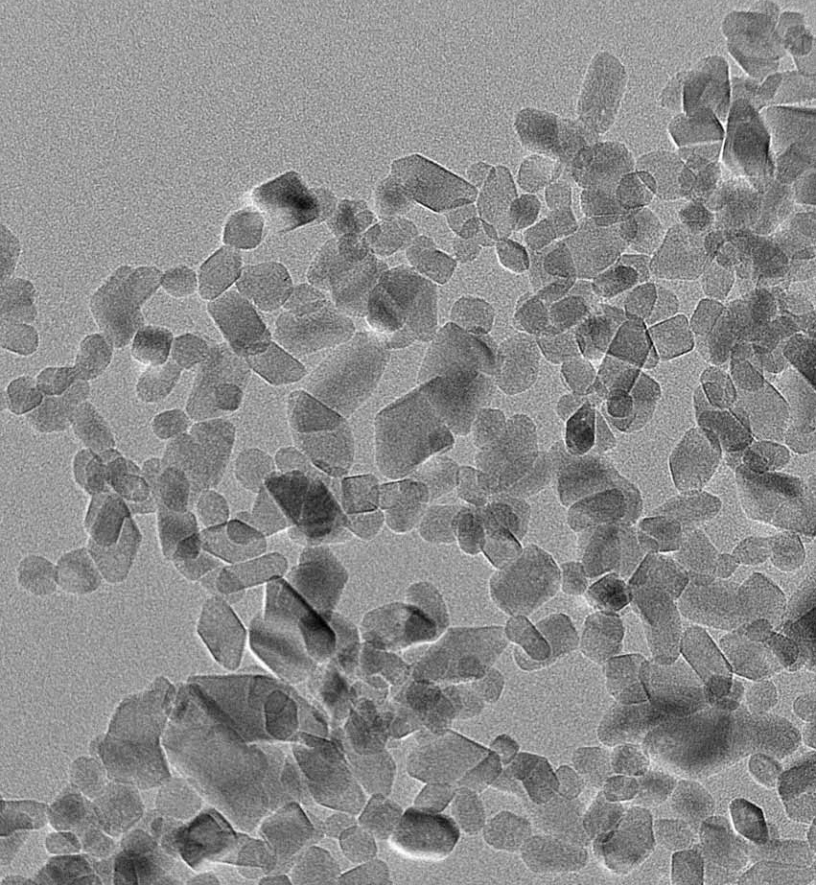

Physical property 6: Energy conversion (titania nanoparticles)

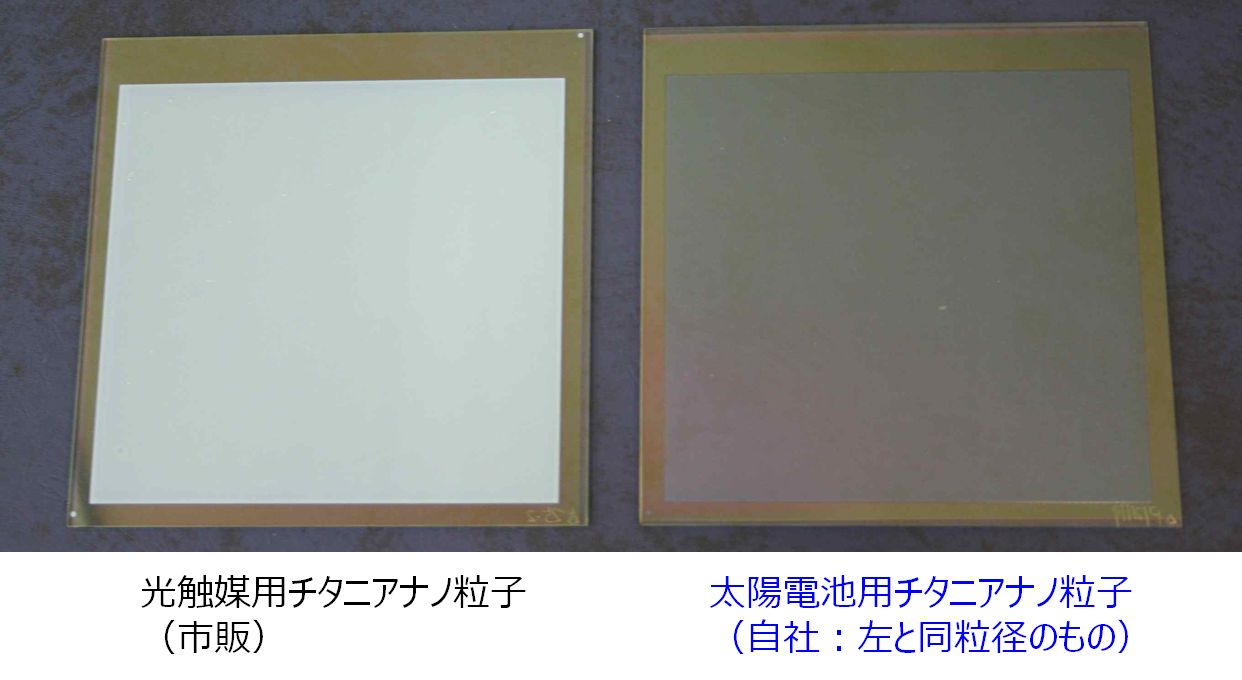

Titania nanoparticles are 10–20 nm anatase crystals, which are larger than titania sols. When used on the negative electrode of a dye-sensitized solar cell, titania nanoparticles exhibit energy conversion efficiency relatively 20% higher than that of ordinary photocatalysts due to their high transparency and high surface activity.

They can also be used on the negative electrodes of see-through dye-sensitized solar cells and perovskite photovoltaic cells.

Fig. 14. Energy conversion efficiency of dye-sensitized solar cells

Fig. 15. Titania nanoparticles for solar cells

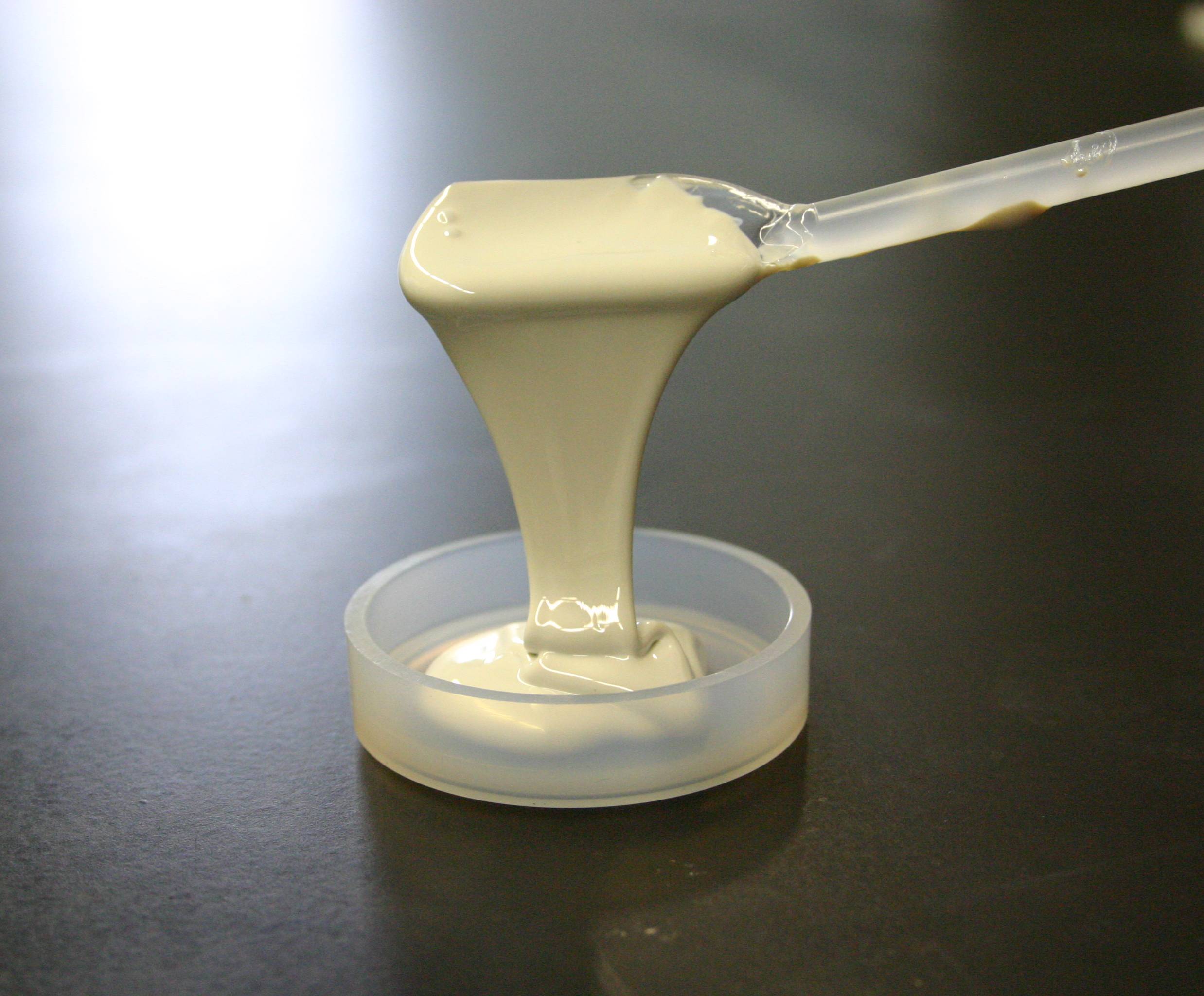

Figure 16. Titania paste for solar cells

Fig. 17. Transparency comparison between titania for general photocatalysts and titania for solar cells (same particle size)

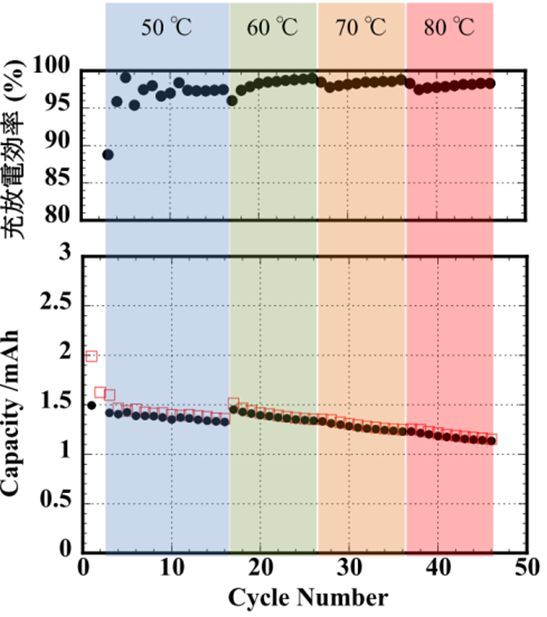

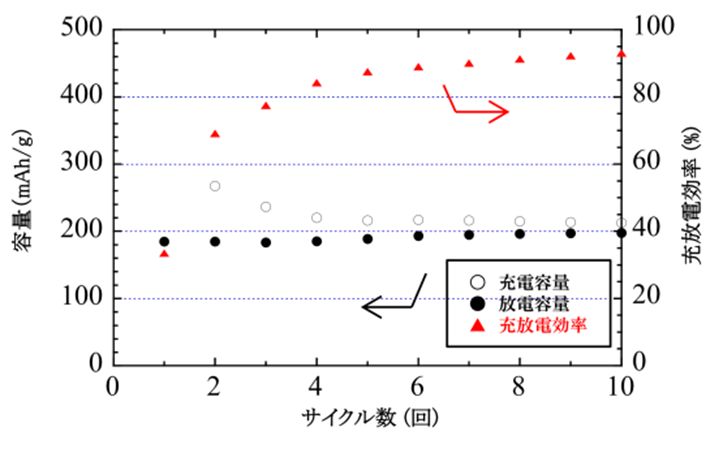

Physical property 7: Charge/discharge characteristics (titanate nanomaterials)

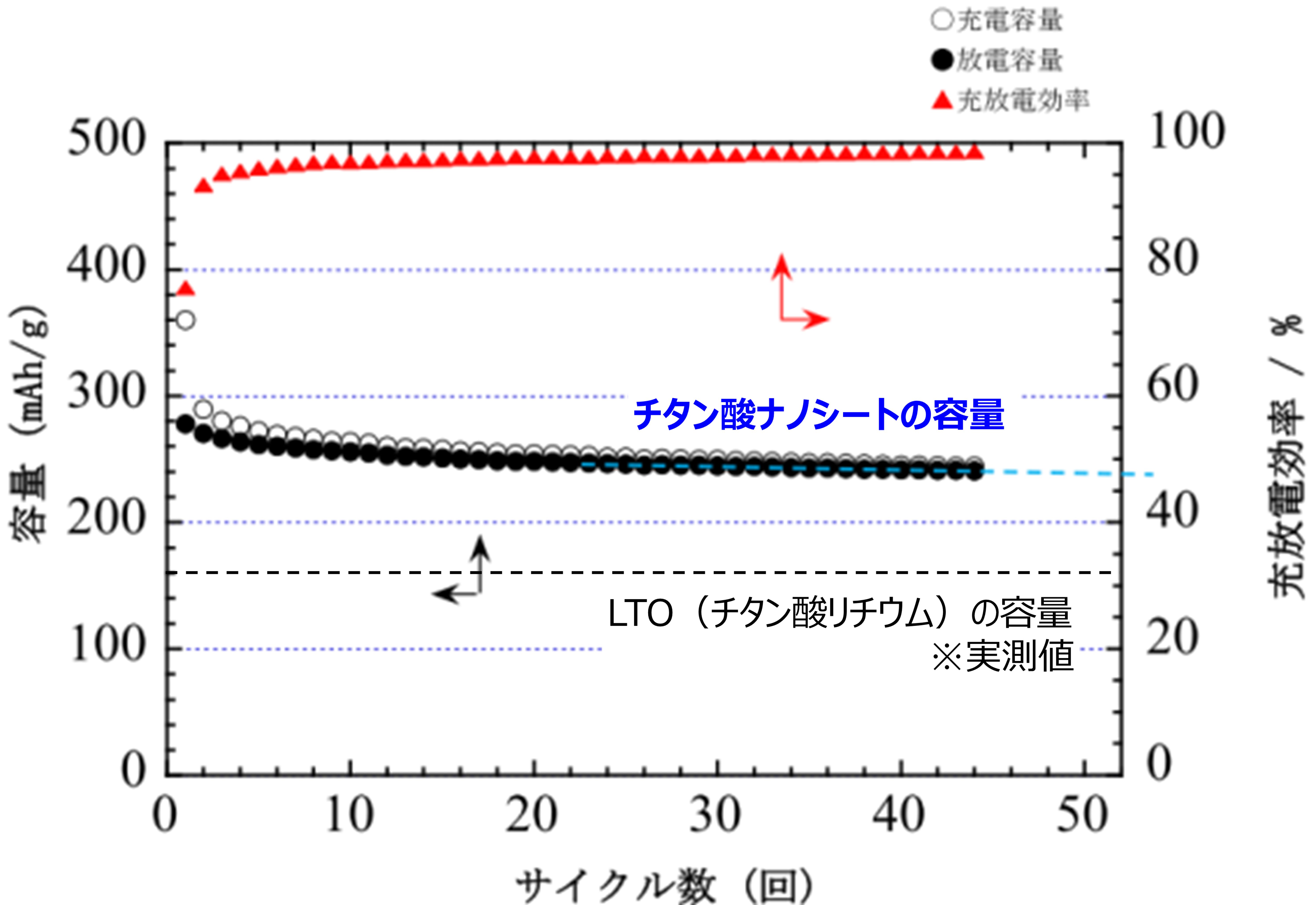

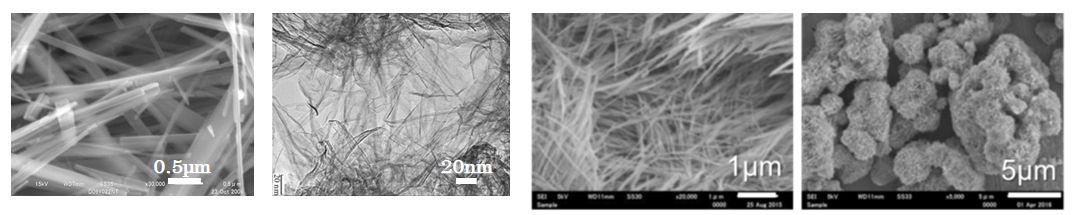

Titanate nanomaterials (nanosheets, nanofibers, etc.) have the safety of titanium-based materials, but are superior to conventional titanium-based anode materials in terms of energy density and rate characteristics.

Because of its high electric potential, the titanate nanomaterial is unlikely to cause the electrolyte to decompose, implying its potential to enable a highly heat-resistant secondary battery to be fabricated using an ionic liquid.

It has sodium ion charging/discharging properties and may be used for sodium ion secondary batteries.

Its properties also include strong adsorption of heavy metals and moisture absorption and desorption, so it may be used for adsorption of radioactive substances and for air conditioning purposes in the future.

Fig. 18. Charge/discharge characteristics of the titanate nanomaterial as a lithium-ion battery negative electrode

Fig. 19. Various titanate nanomaterials

Fig. 20. Highly heat-resistant LIB using ionic liquid (prototype)

Fig. 21. Sodium ion charging/discharging (prototype)

Related contents

TAG SEARCH

- Evolving residential gas appliances

- Evolving residential gas appliances Water heaters, space heaters, dryers Cooking appliances Smart Equipment Fuel Cell systems

- Evolving commercial and industrial gas appliances

- Evolving commercial and industrial gas appliances Cogeneration (CHP) units Air conditioning systems, kitchen appliances Bio, water treatment Industrial furnaces, burners Energy management, IoT

- Enhancing the safety and economic efficiency of LNG regasification

- Enhancing the safety and economic efficiency of LNG regasification Utilization of cold energy Plant materials Power generation technology

- Developing next-generation businesses through enterprising initiatives

- Developing next-generation businesses through enterprising initiatives Materials development Measurement Simulation, data analysis Food science Material evaluation

- Contributing to conserving the environment and achieving a carbon neutral society

- Contributing to conserving the environment and achieving a carbon neutral society Methanation Hydrogen, ammonia Biogas Energy management Renewable Energy

- Technologies of Group companies

- KRI, Inc. Osaka Gas Chemicals Group OGIS-RI Group