Water heaters, space heaters, dryers

Energy-saving, High-efficiency Water Heater Eco-Jozu

Overview

The Kyoto Protocol sets forth the goal of reducing greenhouse gas emissions by 6% (compared to 1990). To achieve this goal, the Guideline for Measures to Prevent Global Warming was revised in March 2002, setting a lofty target of a 2% reduction for the residential sector. Along with this, the guideline lists “Promotion of the diffusion of high-efficiency heating appliances” (top runner approach) as the most important item to be addressed for the mitigation of global warming and the promotion of energy conservation.

As indicated above, there is a high social demand for high-efficiency water heaters. Accordingly, a government subsidy program has also been implemented for the installation of high-efficiency water heaters. Heat source units for room heating and water heating, or heat source units for gas-fired central room heating and water heating systems, have become popular in the market, as they have the hot water supply capability required for the shower and kitchen, for reheating the water in the bathtub, and for the floor heating system, the bathroom heater/dryer, and other room heating appliances. Water heating and room heating account for the majority of household energy consumption. Energy saving in these areas helps reduce CO2 emissions and meet other environmental challenges. Therefore, Osaka Gas has developed a high-efficiency heat source unit for room heating and water heating, utilizing latent heat recovery* technology.

* Latent heat recovery refers to recovering heat from the process of condensing steam contained in exhaust gas to water.

Features

1.High Energy-saving Performance

The thermal efficiency of appliances of the previous type (non-latent heat recovery type) was about 80% during both water heating and room heating. Incorporating the technique of recovering latent heat from combustion exhaust gas, this appliance achieves significantly high levels of efficiency of approximately 95% during water heating and approximately 89% during room heating. This saves energy by approximately 13% compared to appliances of the previous type and reduces running cost.

2.High Environmental Performance from a Comprehensive Perspective

This appliance emits less CO2 than previous models by approximately 13% due to improved energy-saving performance. In addition, it incorporates a power saving mode to reduce standby power consumption and also achieves low NOx emissions. Moreover, its friendliness to the environment includes non-styrofoam packing, avoiding the use of styrofoam in packing.

3.Key Points in High-efficiency Technology

Secondary heat exchangers for recovering latent heat are divided into the flexible pipe type made of stainless steel with excellent acid resistance, the finless water pipe type, and other types. For the purification of drainage (acidic condensate) produced during latent heat recovery, we have developed a neutralization device that uses calcium carbonate natural stone as a neutralizer. The neutralization device is almost maintenance free, filled with a neutralizer to an amount sufficient for 15 years of use.

4.Development of a Drainage Purification Method for Wider Use: New Housing Complexes

Osaka Gas has been selling latent-heat-recovering room heating and water heating systems for newly built housing complexes since fiscal 2002. Housing complexes require the system to have a vertical drain pipe to discharge drainage, which was not required with the previous type. As a solution to this issue, the need for a vertical drain pipe inside the pipe shaft on which the system is installed has been eliminated by providing a built-in pump to pump drainage to the bathroom. This design facilitates the system’s installation on pipe shafts, as with appliances of the previous type, and is accelerating the system’s spread to housing complexes.

5.Development of a Drainage Purification Method for Wider Use: Existing Housing Complexes

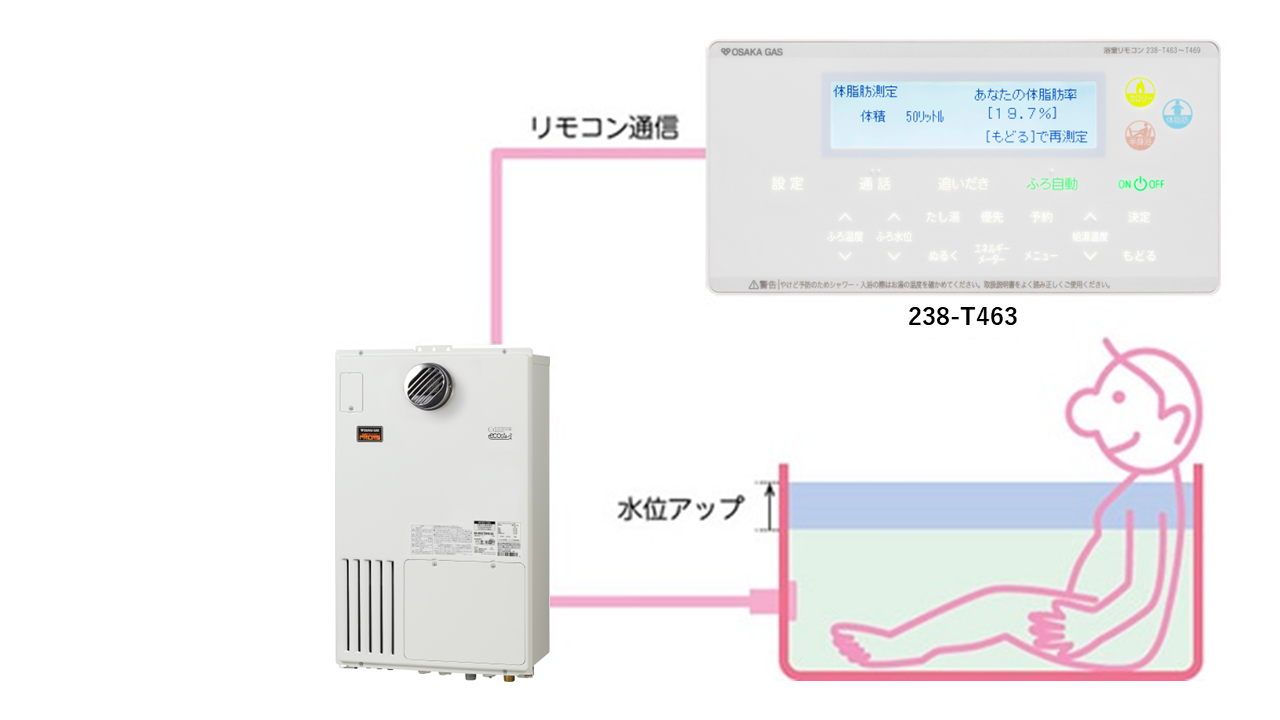

Installing a latent-heat-recovering water heater in an existing housing complex required additional piping for discharging drainage. In such cases, however, installation work was not always simple. Our solution to this challenge was to install a dedicated three-way valve unit inside the bathtub apron so that drainage is fed to the draining outlet via existing piping. This design has made it easier for existing housing complexes to select the high-efficiency system.

Related contents

TAG SEARCH

- Evolving residential gas appliances

- Evolving residential gas appliances Water heaters, space heaters, dryers Cooking appliances Smart Equipment Fuel Cell systems

- Evolving commercial and industrial gas appliances

- Evolving commercial and industrial gas appliances Cogeneration (CHP) units Air conditioning systems, kitchen appliances Bio, water treatment Industrial furnaces, burners Energy management, IoT

- Enhancing the safety and economic efficiency of LNG regasification

- Enhancing the safety and economic efficiency of LNG regasification Utilization of cold energy Plant materials Power generation technology

- Developing next-generation businesses through enterprising initiatives

- Developing next-generation businesses through enterprising initiatives Materials development Measurement Simulation, data analysis Food science Material evaluation

- Contributing to conserving the environment and achieving a carbon neutral society

- Contributing to conserving the environment and achieving a carbon neutral society Methanation Hydrogen, ammonia Biogas Energy management Renewable Energy

- Technologies of Group companies

- KRI, Inc. Osaka Gas Chemicals Group OGIS-RI Group