Industrial furnaces, burners

HEC Fryer

Overview

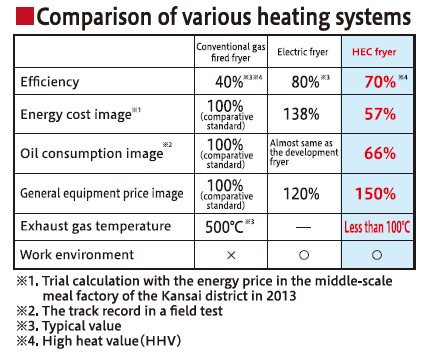

Continuous fryers are used by food service providers, caterers, and convenience store vendors. Conventional gas-powered fryers have the following issues.

・Exhaust gas is discharged to the production site at a high temperature (about 500℃), causing deterioration of the work environment.

・Efficiency is as low as 40%, resulting in higher fuel costs.

・Uneven heating of the oil tank accelerates deterioration of oil due to local heating.

Osaka Gas has developed a high-efficiency continuous fryer that can solve these issues.

Comparison of Various Fryer Heating Systems

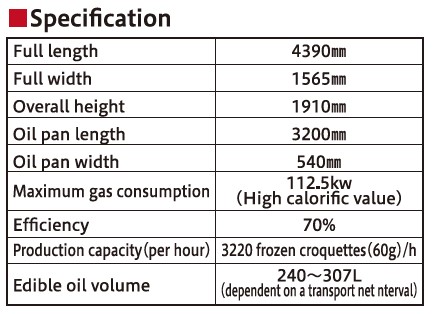

Specifications

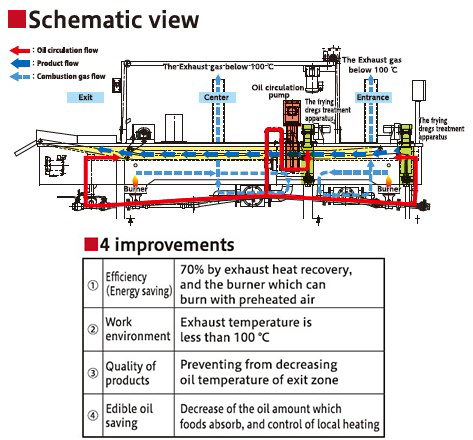

Features of Equipment

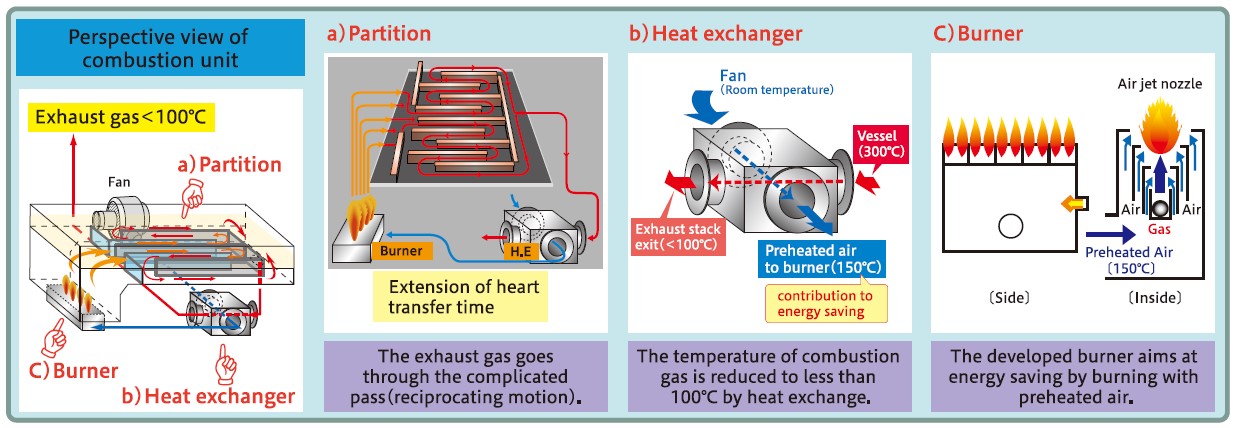

The heating system has been improved to achieve a high efficiency. The exhaust temperature can be reduced to less than 100℃, which is lower than the oil temperature, contributing to the improvement of the work environment!

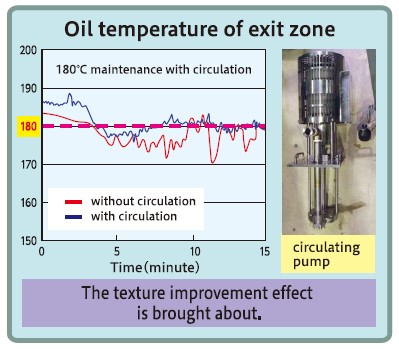

The oil circulation pump keeps the outlet temperature at a high temperature, so the texture of fried food is improved!

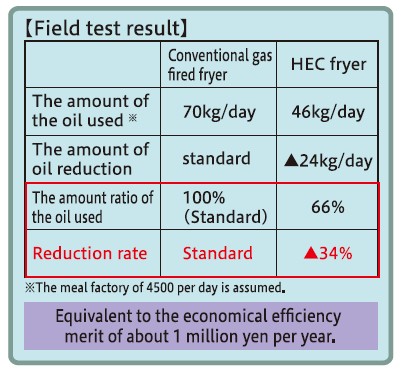

Oxidation is mitigated by reducing local heating of oil, and oil consumption is reduced by improving the removal of oil from fried food!

Related contents

TAG SEARCH

- Evolving residential gas appliances

- Evolving residential gas appliances Water heaters, space heaters, dryers Cooking appliances Smart Equipment Fuel Cell systems

- Evolving commercial and industrial gas appliances

- Evolving commercial and industrial gas appliances Cogeneration (CHP) units Air conditioning systems, kitchen appliances Bio, water treatment Industrial furnaces, burners Energy management, IoT

- Enhancing the safety and economic efficiency of LNG regasification

- Enhancing the safety and economic efficiency of LNG regasification Utilization of cold energy Plant materials Power generation technology

- Developing next-generation businesses through enterprising initiatives

- Developing next-generation businesses through enterprising initiatives Materials development Measurement Simulation, data analysis Food science Material evaluation

- Contributing to conserving the environment and achieving a carbon neutral society

- Contributing to conserving the environment and achieving a carbon neutral society Methanation Hydrogen, ammonia Biogas Energy management Renewable Energy

- Technologies of Group companies

- KRI, Inc. Osaka Gas Chemicals Group OGIS-RI Group