Simulation, data analysis

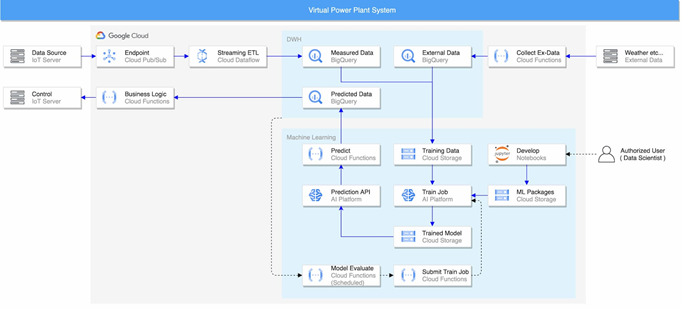

Development of an Analysis Platform Capable of Real-time Processing of Tens of Thousands of IoT Devices

Overview

The Business Analysis Center of Osaka Gas is working on developing a real-time analysis platform that analyzes and processes data sent from the company’s tens of thousands of IoT devices in real time.

Purpose

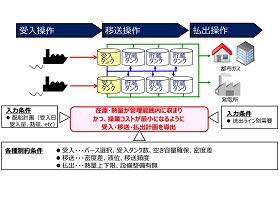

Due to the rapid increase in the amount of data resulting from the increase in the number of IoT devices managed by Osaka Gas, it is becoming difficult to analyze data in the existing environment created by the company. Moreover, in recent years, there has been a demand for systems that require real-time data analysis, machine learning, and control computation, as typified by virtual power plants, so it was necessary to develop a real-time IoT analysis platform.

System Configuration

Concept

This system not only collects and processes data in real time but also automatically performs machine learning. In addition, efforts are under way to automate accuracy monitoring and re-learning.

It is likely that the result will be a fully automated real-time analysis platform operated with much fewer staff, allowing the company’s IoT services to be expanded and enhanced.

Action

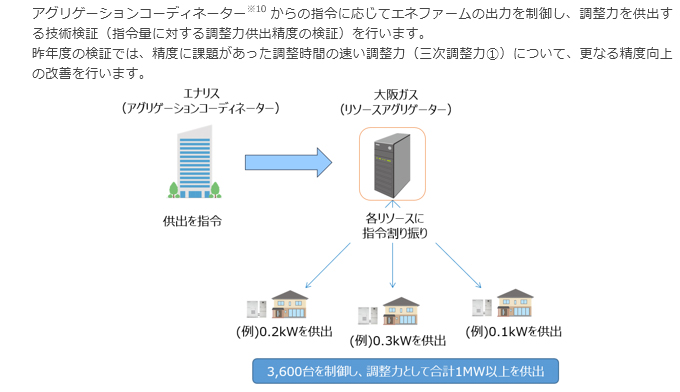

We participated in the Ministry of Economy, Trade and Industry’s Demonstration Project for Building Virtual Power Plant (FY2021) as a resource aggregator, controlled about 3,600 units of Ene-Farm, and established technology that could be active in actual business settings.

Related contents

TAG SEARCH

- Evolving residential gas appliances

- Evolving residential gas appliances Water heaters, space heaters, dryers Cooking appliances Smart Equipment Fuel Cell systems

- Evolving commercial and industrial gas appliances

- Evolving commercial and industrial gas appliances Cogeneration (CHP) units Air conditioning systems, kitchen appliances Bio, water treatment Industrial furnaces, burners Energy management, IoT

- Enhancing the safety and economic efficiency of LNG regasification

- Enhancing the safety and economic efficiency of LNG regasification Utilization of cold energy Plant materials Power generation technology

- Developing next-generation businesses through enterprising initiatives

- Developing next-generation businesses through enterprising initiatives Materials development Measurement Simulation, data analysis Food science Material evaluation

- Contributing to conserving the environment and achieving a carbon neutral society

- Contributing to conserving the environment and achieving a carbon neutral society Methanation Hydrogen, ammonia Biogas Energy management Renewable Energy

- Technologies of Group companies

- KRI, Inc. Osaka Gas Chemicals Group OGIS-RI Group