Hydrogen, ammonia

Development of Chemical Looping Combustion Technology for Simultaneous Generation of Hydrogen, Electricity, and CO₂

Overview

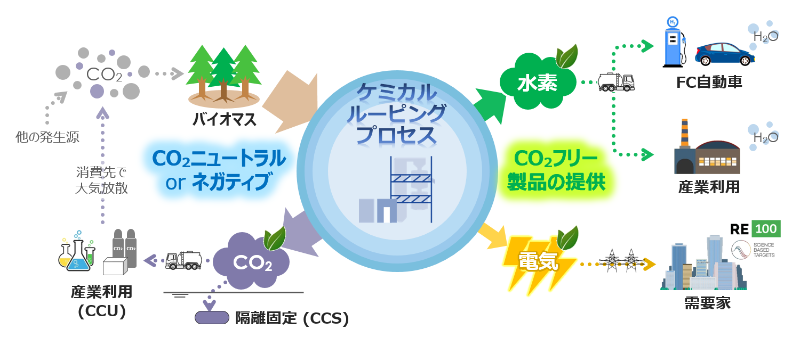

Osaka Gas is working on developing CLC*1 technology that can simultaneously generate hydrogen, electricity, and CO2 using the redox reaction of iron oxide. Our company aim of helping customers decarbonize by generating and supplying green hydrogen and other products using biomass-direct CLC technology.

*1. CLC: Chemical Looping Combustion

Commercialized CLC technology envisioned by Osaka Gas

Background

CLC technology is a technology that can simultaneously generate hydrogen, electricity and CO2 by circulating iron oxide and reacting it with fuel, water, and air.Coal and biomass can be used as the fuel.

When biomass, which is a carbon-neutral fuel, is used as a fuel, this technology is expected to generate and supply green hydrogen, electricity, and biomass-derived CO2.

Meanwhile, there have been no examples of implementation of CLC technology that generate hydrogen using biomass as fuel. Accordingly, for practical use of the technology, it is necessary to overcome technical challenges such as development of elemental technology and process verification for the establishment of system design technology.

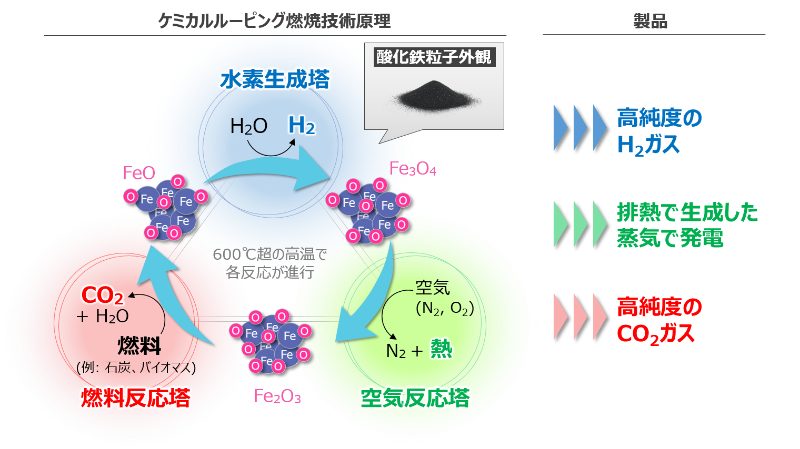

Principle

CLC is a technology that uses the redox reaction of iron oxide. While iron oxide circulates through three reactors (fuel reactor, hydrogen reactor, and air reactor), In each reactor, the reaction of iron oxide with fuel, water, and air generates hydrogen, electricity, and CO2, respectively.

<Fuel Reactor> The fuel reacts with the oxygen in iron oxide. Then CO2 is generated.

<Hydrogen Reactor> H2O reacts with iron oxide in oxygen deficient state. Then H2 is generated.

<Air reactor> O2 reacts with iron oxide, making it the most oxidized state. Then N2 and Heat is generated.

Since the reaction in air reactor is a large exothermic reaction, this generated heat is used for power generation.

Principle of chemical looping combustion (CLC) technology

Development Description

Research and development aimed at the practical application of CLC technology is being conducted by Osaka Gas Co., Ltd. and Japan Coal Frontier Organization (JCOAL). This project is being implemented by NEDO (*2)'s " Development of technologies for a poly-generation system with CO2 separation/capture capabilities " project (*3) (FY2020-2024). This project involves the development of elemental technologies for CLC technology that uses coal and biomass as fuel, and the process demonstration of a 300 kW (*4) demonstration plant.

*2. NEDO: New Energy and Industrial Technology Development Organization

*3. Official project title: Development of Technologies for Carbon Recycling and Next-Generation Thermal Power Generation/Development of Fundamental Technologies for Next-generation Thermal Power/ Development of technology for a poly-generation system with CO2 separation/capture capabilities / Development of technology for chemical looping combustion poly-generation. (https://www.nedo.go.jp/english/activities/activities_ZZJP_100115.html)

*4. Calorific value of supplied fuel per unit time

A cold model demonstration plant installed on the premises of Osaka Gas Co., Ltd. for the purpose of understanding the circulating flow characteristics of iron oxide.

Related contents

TAG SEARCH

- Evolving residential gas appliances

- Evolving residential gas appliances Water heaters, space heaters, dryers Cooking appliances Smart Equipment Fuel Cell systems

- Evolving commercial and industrial gas appliances

- Evolving commercial and industrial gas appliances Cogeneration (CHP) units Air conditioning systems, kitchen appliances Bio, water treatment Industrial furnaces, burners Energy management, IoT

- Enhancing the safety and economic efficiency of LNG regasification

- Enhancing the safety and economic efficiency of LNG regasification Utilization of cold energy Plant materials Power generation technology

- Developing next-generation businesses through enterprising initiatives

- Developing next-generation businesses through enterprising initiatives Materials development Measurement Simulation, data analysis Food science Material evaluation

- Contributing to conserving the environment and achieving a carbon neutral society

- Contributing to conserving the environment and achieving a carbon neutral society Methanation Hydrogen, ammonia Biogas Energy management Renewable Energy

- Technologies of Group companies

- KRI, Inc. Osaka Gas Chemicals Group OGIS-RI Group